Innovative Design Approaches for a Green Fashion Future

As the world moves toward a more sustainable future, the fashion industry stands at a pivotal crossroads. Innovative design approaches are not only reshaping what we wear, but redefining how clothing impacts the planet. A commitment to green fashion requires visionary thinking, cutting-edge technology, and a willingness to challenge traditional methods. This page explores how creative strategies in design are paving the way for an environmentally conscious fashion landscape, ensuring aesthetics and ethics can coexist harmoniously.

Circular Design Principles

One of the most impactful shifts in sustainable fashion involves designing garments to last. Durability is achieved through the careful selection of high-quality materials and construction techniques that withstand repeated wear and washing. This approach requires designers to focus on timeless styles rather than fast-moving trends, encouraging consumers to cherish and care for their pieces. Ultimately, prioritizing longevity helps curb the rampant overconsumption and waste synonymous with fast fashion, laying a foundation for apparel that serves people and planet for years to come.

Innovations in bio-based and regenerative fibers are revolutionizing sustainable textiles. Plant-derived fibers like hemp, flax, and bamboo, as well as game-changing options such as mycelium leather and pineapple leaves, offer renewable alternatives to conventional synthetics and animal products. Many of these materials require fewer resources, sequester carbon, and even contribute to soil health. Designers who incorporate these fibers directly support biodiversity, reduce dependency on fossil fuels, and create garments that are biodegradable, setting new standards for eco-consciousness.

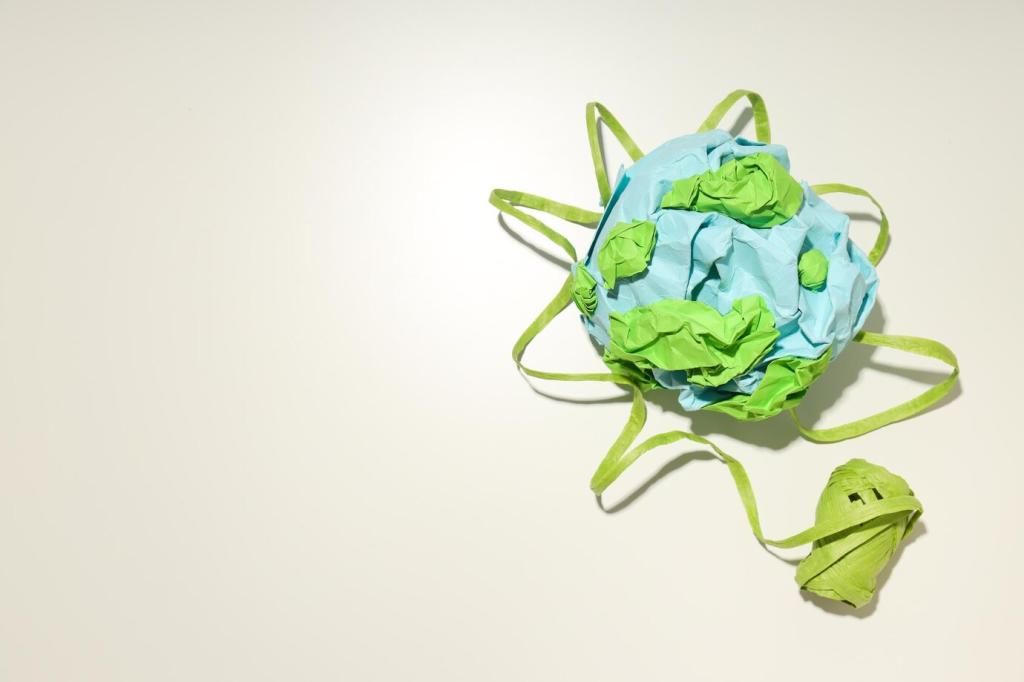

Upcycling breathes new life into pre-existing resources, turning what might be wasted into unique, valuable garments. Designers scour factories, warehouses, and post-consumer waste streams to source deadstock fabrics—materials that would otherwise languish unused and eventually be disposed of. Through creative pattern-making and innovative design, these textiles are reimagined into new collections, each piece telling a story of waste diverted. This approach not only conserves resources but also encourages limited-edition, one-of-a-kind fashion that resonates with consumers’ desire for meaningful, responsible purchases.

Traditional dyeing processes account for significant water consumption and chemical pollution in the fashion industry. Embracing waterless or low-impact dyeing technologies represents a profound shift toward sustainability. Techniques such as digital printing, plant-based dyes, and CO2 dyeing drastically reduce water usage and eliminate hazardous effluents. By considering the environmental cost of color, designers are able to deliver vibrant, high-quality garments with a fraction of the ecological footprint, significantly contributing to cleaner waterways and healthier communities near manufacturing hubs.

Technological Innovations in Production

3D Modeling and Virtual Sampling

The adoption of 3D modeling in the design phase is revolutionizing how garments are developed and brought to market. With virtual sampling, designers can craft accurate, detailed prototypes without the need for physical samples, dramatically slashing material waste and energy consumption. Iterative changes can be visualized and assessed in real time, reducing both lead times and costs. This digital workflow not only streamlines the creative process but also allows for enhanced collaboration and customer visualization, helping ensure that fashion can innovate sustainably from the very first sketch.

On-Demand and Made-to-Order Manufacturing

Traditional fashion production produces surpluses that often end up as waste due to inaccurate demand forecasting. On-demand and made-to-order manufacturing models are shifting this paradigm by producing garments only when a customer places an order. Powered by digital technology and agile supply chains, these methods cut overproduction, minimize unsold stock, and significantly lower waste. Every garment produced directly responds to real consumer needs, strengthening the alignment between supply, demand, and sustainability, while also catering to desires for personalized fashion experiences.

Automation and Zero-Waste Pattern Cutting

Advanced automation in pattern cutting and sewing is empowering fashion brands to tackle inefficiencies in garment manufacturing. Zero-waste pattern cutting techniques, facilitated by sophisticated software, ensure that every inch of fabric is utilized, producing minimal leftover materials. Automated systems reduce human error, optimize resource usage, and enable the creation of complex, precisely engineered garments. By combining creative design with technical innovation, fashion houses can achieve significant reductions in waste and costs, signals of progress within a green fashion future.